Unlock the Answers to FZG Gear Testing | FAQ Sheet

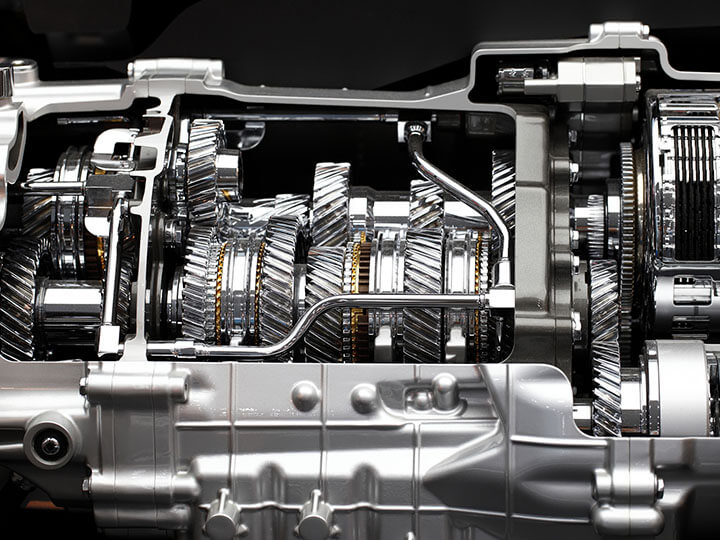

FZG testing remains one of the most trusted and widely used methods in the automotive industry for evaluating how lubricants and gear systems perform under real-world conditions — from scuffing and wear to pitting and micropitting. Whether you’re developing next-generation e-fluids, benchmarking new additive chemistries, or validating components for OEM approval, understanding the fundamentals of FZG is essential for drivetrain durability and reliability.

Our FZG Testing FAQ brings together many of the most common questions engineers ask — along with clear, concise answers you can use to accelerate development, reduce risk, and meet performance requirements with confidence.

Inside, you’ll discover:

- How FZG testing replicates real-world drivetrain conditions in a controlled laboratory environment

- Which failure modes (such as scuffing, wear, and micropitting) matter most for long-term gear and lubricant performance

- The key ASTM, CEC, and ISO standards that apply — and how to interpret test results effectively

- Why FZG testing is a critical step in OEM validation programs and e-fluid formulation

Get Instant Access

Complete the short form below to download your free copy of the FZG Testing FAQ. Once submitted, you’ll receive immediate access and can start applying these insights to your next drivetrain program.

d, you’ll get immediate access and can start applying these insights to your next drivetrain program.